How to Install a Butterfly Valve (2” & 3”) in Industrial Pipelines – Step-by-Step for Beginners

How to Install a Butterfly Valve (2” & 3”) in Industrial Pipelines – Step-by-Step for Beginners

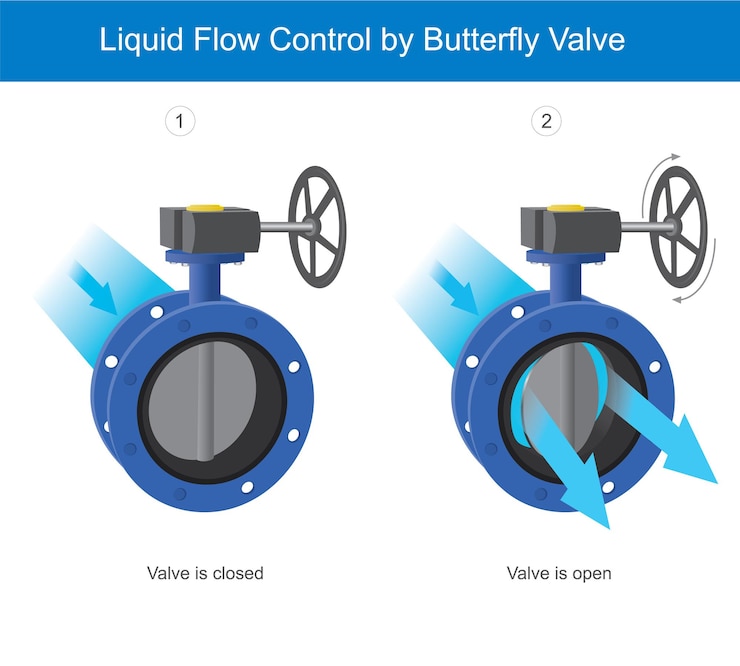

Installing a butterfly valve in an industrial pipeline may seem intimidating at first, especially for beginners. But with the right tools, a bit of technical know-how, and a proper step-by-step approach, it becomes a manageable and highly rewarding task. In industries across Pakistan, butterfly valves are widely used due to their compact design, quick shut-off capability, and affordability.

Whether you’re dealing with water, oil, gas, or chemicals, the correct installation of a butterfly valve ensures efficient flow control and long-term reliability. This guide focuses on the installation of 2-inch and 3-inch butterfly valves and is tailored for industrial use cases in Pakistan.

We’ll be referencing Featured Products such as the Butterfly Valve CI Body Dia:2”, Butterfly Valve CI Body Dia:3”, and the Butterfly Valve Lever Handle LD Taiwan, all built for durability, precision, and performance.

Why Use a Butterfly Valve in Industrial Pipelines?

Butterfly valves are quarter-turn valves used to regulate or isolate flow. Their disc-type design makes them highly effective for systems requiring quick shut-off with minimal space. In Pakistan’s industrial sectors like water treatment, HVAC, petroleum, and food processing, butterfly valves are essential for efficient fluid control.

Key Advantages:

- Lightweight and compact design

- Quick operation (90° turn)

- Lower cost compared to other valve types

- Suitable for large pipe diameters

- Easy to maintain

Tools & Materials Required for Installation

To begin installation, gather the following equipment and supplies:

- Butterfly valve (2” or 3”)

- Corresponding flanged pipe ends

- Pipe gaskets (if applicable)

- Flange bolts, nuts, and washers

- Torque wrench

- Pipe wrench or spanner set

- Screwdriver (for lever-type handle)

- Anti-seize compound or thread sealant

- Clean cloth

- Personal protective gear (gloves, safety glasses)

Step-by-Step Installation Guide

The steps below apply to both Butterfly Valve CI Body Dia:2” and Butterfly Valve CI Body Dia:3”. Follow each step carefully to ensure a safe and leak-free installation.

Inspect the Valve and Piping System

Before installation, thoroughly inspect the valve:

- Ensure that the disc rotates freely and without resistance

- Check for any shipping damage or manufacturing defects

- Clean both the valve body and the inside of the pipe ends

- Confirm flange face condition and remove debris, rust, or oil residues

Align the Valve Between the Flanges

- Position the valve centrally between the pipeline flanges.

- Make sure the disc is slightly open (10-15°) to prevent it from coming into contact with the flange faces during installation.

- Insert bolts through both flanges, securing the valve gently in place.

For both 2” and 3” valves, alignment is critical to ensure a proper seal and unrestricted disc movement.

Insert Gaskets If Required

Some butterfly valves have integrated linings that act as seals. However, depending on the media and pressure class, you may require additional gaskets:

- Use compatible gasket material (EPDM, PTFE, etc.)

- Center the gasket properly around the valve opening

- Avoid overlapping the disc area

Tighten Bolts Using a Star Pattern

To prevent uneven pressure or flange distortion:

- Use a cross-bolt tightening sequence (i.e., tighten opposite bolts gradually)

- Tighten all bolts finger-tight first

- Then use a torque wrench to secure each bolt to the manufacturer-recommended torque setting

- Apply anti-seize lubricant on bolts if necessary for future maintenance ease

Uneven tightening can damage the valve body or cause leaks under pressure.

Test the Disc Movement

Before the system is pressurized:

- Manually operate the valve using the handle or actuator

- Ensure that the disc opens and closes fully without obstruction

- Confirm that the valve doesn’t contact the inner wall of the pipe or the gasket

This is especially important for the Butterfly Valve Lever Handle LD Taiwan, as manual operation must be smooth and accurate.

Install the Handle or Actuator

For manual operations, install the Butterfly Valve Lever Handle LD Taiwan:

- Position the handle onto the valve stem

- Secure it with the locking bolt or screw

- Check for clear open/close markings

- Test operation again after tightening

If you’re using an electric or pneumatic actuator, follow the manufacturer’s wiring and pressure guidelines.

Perform a Pressure Test

Now it’s time to verify your installation:

- Gradually introduce pressure into the pipeline

- Observe the valve for any signs of leaks, vibrations, or abnormal noise

- Leave the valve in fully closed, half-open, and fully open positions to check sealing integrity

- Tighten bolts slightly if minor leakage is detected during the test

This step is crucial before putting the pipeline into full operational mode.

Document the Installation

After a successful test:

- Record the valve model, size, and installation date

- Note down torque settings and test results

- Keep this information in your maintenance log for future reference

This will make future servicing or replacement quicker and more efficient.

Schedule Regular Maintenance Checks

While butterfly valves arek low-maintenance, regular checks help extend lifespan:

- Operate the valve once a month to prevent seizing

- Inspect for signs of corrosion, wear, or leakage

- Lubricate moving parts if necessary

- Replace worn gaskets or handles promptly

Application Areas in Pakistan’s Industrial Sector

Butterfly valves like the Butterfly Valve CI Body Dia:2” and Butterfly Valve CI Body Dia:3” are commonly used across:

- Water supply and drainage systems

- HVAC pipelines

- Petrochemical processing units

- Cement and construction industries

- Agricultural irrigation networks

- Manufacturing and chemical plants

Due to the diversity of industrial applications in Pakistan, choosing the right valve size and material for your specific environment is essential for performance and durability.

Where to Get Industrial-Grade Butterfly Valves in Pakistan?

When sourcing butterfly valves for critical applications, quality and reliability should be your top priorities. Whether you need a 2” or 3” valve, manual or automated, DayShop.pk offers a trusted selection of industrial valves backed by prompt support and free nationwide delivery.

From high-performance cast iron butterfly valves to robust lever handle controls like the Butterfly Valve Lever Handle LD Taiwan, you’ll find dependable solutions that are built to last in tough Pakistani conditions.

Only the highest standards of industrial quality—available exclusively at DayShop.pk.

Key Takeaways for Beginner Installers

| Component | Details |

|---|---|

| Valve Sizes | 2” (DN50) and 3” (DN80) |

| Products to Use | Butterfly Valve CI Body 2” & 3”, LD Taiwan Handle |

| Installation Type | Flanged, manual handle |

| Common Applications | Water, oil, chemicals, HVAC |

| Maintenance | Monthly operation, leak inspection |

With correct installation and maintenance, butterfly valves can serve reliably for years without operational issues. Whether upgrading an existing pipeline or installing a new system, following this guide will ensure smooth flow control and efficient system performance.

For expert-approved valves at competitive rates and free delivery anywhere in Pakistan, explore industrial-grade solutions at DayShop.pk—a name trusted by engineers and plant managers nationwide.

Tags:

-

Sale!

Miss Ladies Belt

₨ 2,500Original price was: ₨ 2,500.₨ 1,999Current price is: ₨ 1,999. -

Sale!

High Performance Slimming Belt

₨ 9,500Original price was: ₨ 9,500.₨ 8,000Current price is: ₨ 8,000. -

Sale!

AB Energizer Grey

₨ 4,400Original price was: ₨ 4,400.₨ 3,400Current price is: ₨ 3,400. -

Sale!

Hot Shaper Power Belt Waist Trimmer

₨ 2,500Original price was: ₨ 2,500.₨ 2,000Current price is: ₨ 2,000. -

Sale!

Pill Pro, Weekly Pill Organizer

₨ 1,500Original price was: ₨ 1,500.₨ 999Current price is: ₨ 999. -

Sale!

ANTI-EMBOLISM STOCKINGS

₨ 2,500Original price was: ₨ 2,500.₨ 2,000Current price is: ₨ 2,000. -

Sale!

Car Auto AC Fan Cooler And Heater

₨ 3,000Original price was: ₨ 3,000.₨ 2,500Current price is: ₨ 2,500. -

Sale!

Pack Of 6 Glitter Eye And Lip Pencils

₨ 1,200Original price was: ₨ 1,200.₨ 800Current price is: ₨ 800. -

Sale!

Pack of 6 LIP LINER PENCIL

₨ 1,200Original price was: ₨ 1,200.₨ 800Current price is: ₨ 800. -

Sale!

Hair Wig For Men

₨ 5,500Original price was: ₨ 5,500.₨ 4,500Current price is: ₨ 4,500. -

Sale!

Classic Shaker Bottle

₨ 1,500Original price was: ₨ 1,500.₨ 850Current price is: ₨ 850. -

Sale!

Sweat Shaper For Women

₨ 2,500Original price was: ₨ 2,500.₨ 1,800Current price is: ₨ 1,800. -

Sale!

Velform Sauna Slimmer Belt

₨ 2,500Original price was: ₨ 2,500.₨ 1,600Current price is: ₨ 1,600. -

Sale!

Vibra Tone Slimming Weight Control Belt

₨ 6,600Original price was: ₨ 6,600.₨ 5,500Current price is: ₨ 5,500. -

Sale!

Sweat Slim Belt

₨ 2,000Original price was: ₨ 2,000.₨ 1,500Current price is: ₨ 1,500. -

Sale!

Vibro High Performance Slimming Belt

₨ 6,600Original price was: ₨ 6,600.₨ 5,500Current price is: ₨ 5,500.